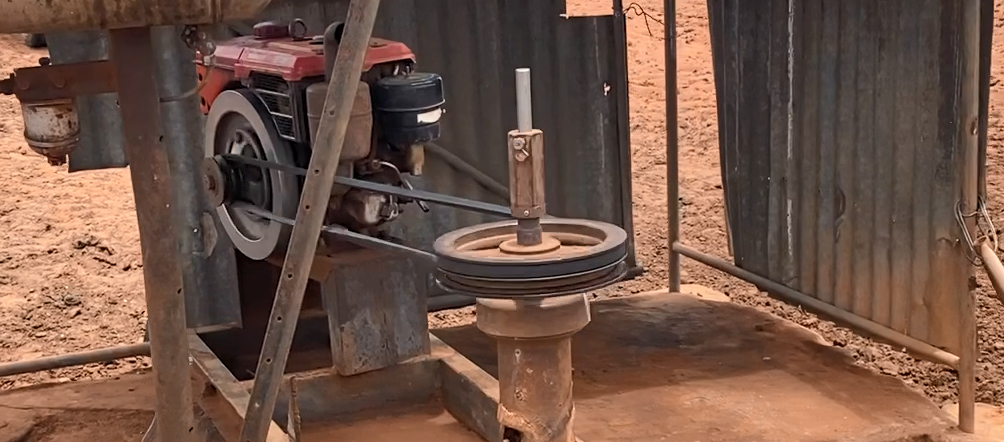

NT WorkSafe has issued a new safety alert after an incident in late December, when a Territory cattle station worker suffered fatal injuries after becoming entangled in the moving parts of a bore pump.

In late December 2020, a Territory cattle station worker failed to return after checking bores on the property.

The worker was later found entangled in a bore pump with fatal injuries.

Preliminary findings indicate the workers clothing got caught in the bore pump’s moving parts.

Possible contributing factors

The pump’s pulley’s and belt were unguarded exposing the worker to a number of hazards including entanglement, friction and abrasion hazards, when the pump was running.

NT WorkSafe’s advice on action required

NT WorkSafe advises that owners and operators of machinery or items of plant must manage the hazards associated with a person coming into contact with the machine’s moving parts.

Its advice includes:

- Isolating a machine’s moving parts using guards is an option to reduce the risk of accidental contact.

- Guards are covers, casing or shields that create a physical barrier preventing a worker (or others), their clothing, personal protective equipment or other accessories from making contact with any moving part.

- Guards should be fitted to prevent contact with:

- Rotating or moving parts;

- Potential crush, shear or nip points on the machine; or

- Parts of the machine which become very hot during normal operations.

- Guards should:

- be of solid construction and securely mounted so as to resist impact or shock;

- be difficult to by-passing or disable, whether deliberate or accidental;

- only be altered or removed by the use of tools;

- not create additional risks such as obstruct an operator visibility or reduce ventilation and cause overheating.

- If the guarded area needs access for maintenance or cleaning, install an interlocked physical barrier that allows access.

- Ensure safety procedures are in place, and understood, when workers have to conduct maintenance of the plant; and

- Ensure workers operating, or working near machines do not have ripped or loose items of clothing, hair, personal protective equipment or jewellery that may get caught.

Source: NT WorkSafe Safety Alert issued 2 Feb 2021

Links to further information:

- Preventing contact or entanglement with machinery or plant with moving parts

- Unguarded grain and fertiliser auger causes serious injury (WorkSafe WA)

- Fatality from entanglement in plant (WorkSafe Victoria)

- Workers caught in conveyor belt system (WorkSafe QLD)

- Managing risks of plant in the workplace (Section 4.1)